Immersive space supports special needs students in Savon ammattiopisto

Immersive space in SAKKY

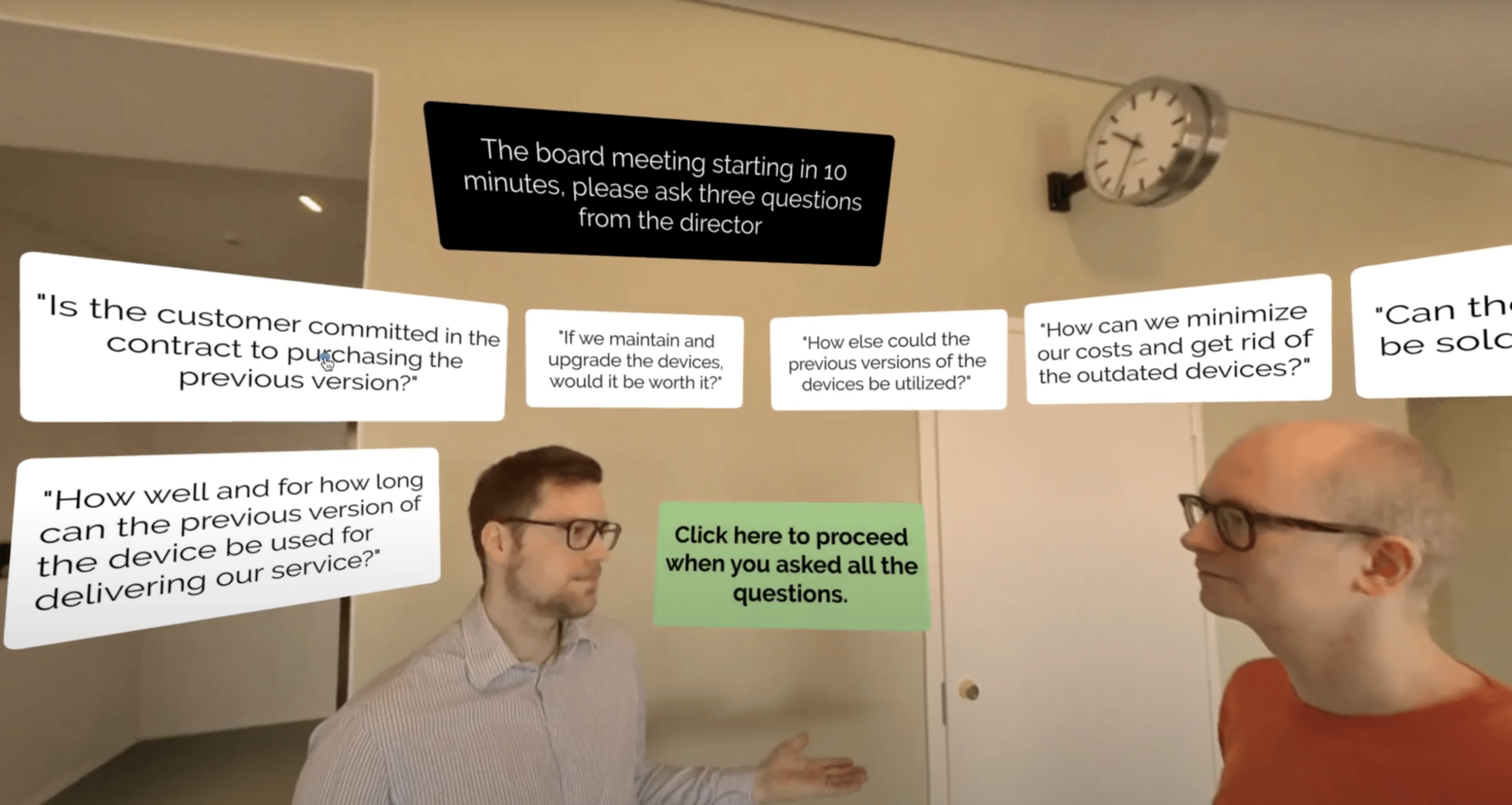

Learning about circular economy in business through a game

Learning about circular economy

3DBear & JAMK Co-Develop AR App for Robot Controlling with AR-Glasses

Controlling Industrial robot with MR glasses

There is a promise in AR/VR technology to help students on the Autism Spectrum to learn better

It all begins with an idea.